➤ What is cast aluminum alloy?

Cast aluminum alloy is an alloy that uses aluminum scrap as the main raw material. After being smelted with copper, silicon, etc., it is processed through casting to produce blanks or parts.1

Cast aluminum alloy is characterized by low density, high strength, good corrosion resistance, excellent castability, and formability. It is a type of alloy semi-finished product primarily used for producing castings and is widely applied in fields such as automobiles, motorcycles, machinery equipment, communication equipment, electronic appliances, and hardware lighting.

1 This type of cast aluminum alloy is often referred to as secondary cast aluminum alloy, which accounts for approximately 80% of the production of cast aluminum alloy. This article specifically refers to secondary cast aluminum alloy.

➤ What is the production process of cast aluminum alloy?

The production process of cast aluminum alloy ingots mainly includes pretreatment, smelting, and casting ingot, with smelting encompassing steps such as melting, alloying, refining, and slag and gas removal. Specifically:

First, non-aluminum metallic and non-metallic scraps are sorted through pretreatment, thoroughly removing oil, paint, and moisture to achieve efficient separation of different types of metals and non-metals, ensuring that the scrap meets smelting requirements.

Secondly, the basic task of smelting is to melt aluminum scrap into molten aluminum, which is then transferred to an alloy furnace and alloyed with corresponding furnace charges. After thorough melting and slag removal, it is sent to a refining furnace for conditioning and refining, with strict control over gas and oxide inclusions, ultimately producing alloy liquid that meets the requirements.

Finally, the molten aluminum alloy liquid is poured into a mold through the casting process. After cooling and solidification, cast aluminum alloy ingots are formed.

➤ What are the common grades of cast aluminum alloy?

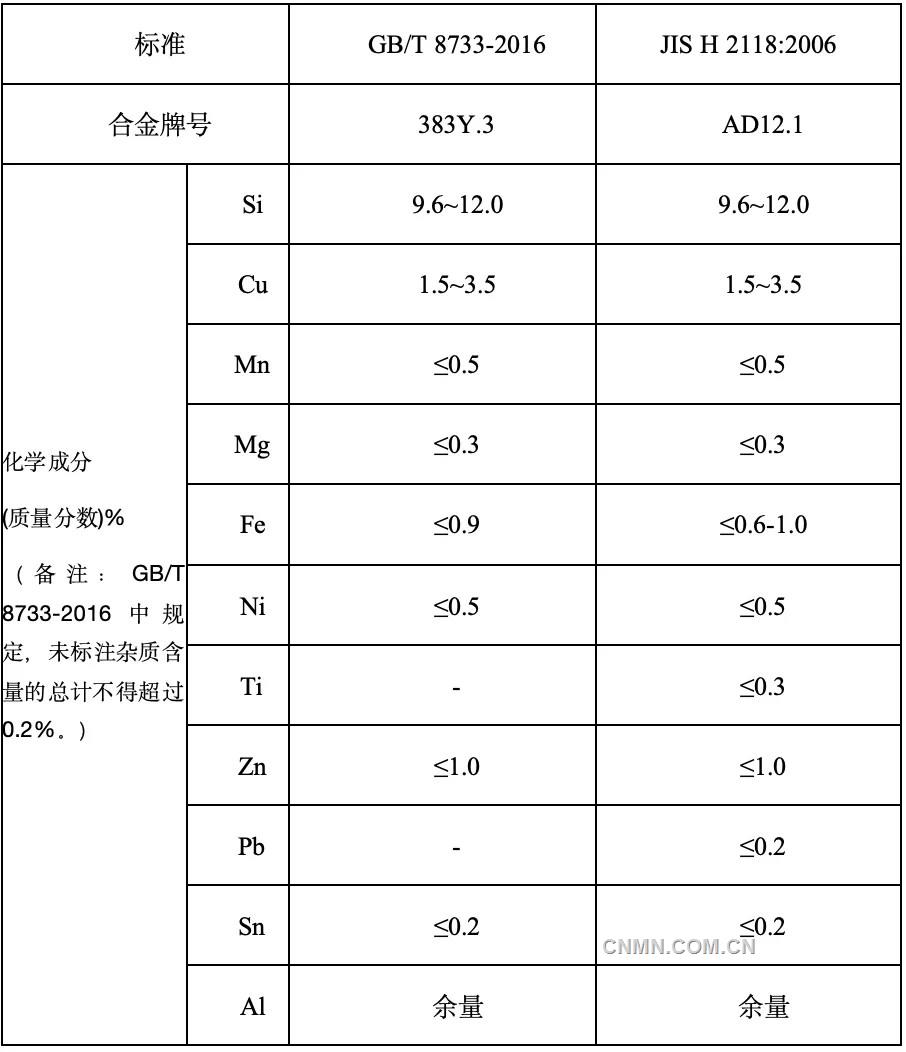

Common grades of cast aluminum alloy include 383Y.3, AD12.1, A380, AlSi9Cu3(Fe), etc. Due to the similar chemical compositions of 383Y.3 and AD12.1, the market collectively refers to these two grades as ADC12.

ADC12 is the mainstream grade of cast aluminum alloy and can be used to manufacture parts such as automobile cylinder blocks, cylinder heads, locomotive shock absorbers, engine gearboxes, agricultural machinery gearboxes, camera bodies, and power tool bodies.

➤ What types of enterprises are involved in the cast aluminum alloy industry chain?

The cast aluminum alloy industry chain covers the entire process from scrap recycling to end-use applications, with core segments divided into raw material supply, midstream manufacturing, and downstream applications.

Raw material suppliers for cast aluminum alloy mainly include aluminum scrap recycling enterprises, aluminum product producers, and aluminum scrap traders. The producers of cast aluminum alloy are often referred to as secondary aluminum plants. Cast aluminum alloy is mainly used to produce die castings or castings, with its downstream application enterprises primarily being die casting plants, automotive parts plants, or automobile assembly plants.

➤ What are the industry standards for cast aluminum alloy?

The national recommended standards in China mainly include GB/T 8733-2016 "Cast Aluminum Alloy Ingots", and 383Y.3 is a grade derived from this standard. Relevant standards in Japan mainly include JIS H 2118:2006 "Aluminum Alloy Die Casting Ingots", and AD12.1 is a grade derived from this standard. Relevant standards in the US mainly include ASTM B85/B85M, etc.

➤ What are the chemical composition requirements for ADC12?

The chemical composition requirements for alloy grade 383Y.3 specified in the national recommended standard GB/T 8733-2016 in China, and alloy grade AD12.1 specified in the Japanese standard JIS H 2118:2006 are shown in the table below.

➤ What are the quality requirements for ADC12 in addition to chemical composition requirements?

In addition to chemical composition, the national recommended standard GB/T 8733-2016 specifies the fracture structure, slag inclusion content, and appearance quality of alloy grade 383Y.3. For example, it stipulates that the fracture structure of the casting ingot should be dense, free from slag and inclusions, and should be visually inspected. It stipulates that the slag inclusion content grade of the casting ingot should not exceed Grade II. It stipulates that the surface of the casting ingot should be clean, free from mildew spots and foreign inclusions, with slight slag inclusion, trimming marks, and slight cracks caused by pouring shrinkage allowed. It stipulates that the pinhole degree is an index to be determined through negotiation between the sellers and buyers, etc.

➤ What is the relationship between cast aluminum alloy, alumina, and aluminum?

Alumina is electrolyzed to produce aluminum, which can be further processed into aluminum alloy products by adding other elements. After being scrapped, aluminum alloy products are recycled and reprocessed into cast aluminum alloy, achieving low-carbon and green recycling.

Source: Shanghai Futures Exchange